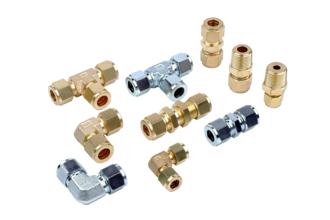

Brass and Carbon Tube Fittings

DK-LOK offers a wide variety of Brass and Carbon tube fittings that are designed using industrial codes and specifications with additional Cutting-Edge Engineering on swaging action and sealing integrity. Our tube fittings provide excellent leak-free sealing on high-pressure gas, vacuum, impulse, thermal shock, heavy vibration, and many other stringent applications.

DK-LOK Tube Fitting consists of body, front ferrule, back ferrule, and nut. The features include:

- Excellent product range up to 2 in. and 50 mm OD.

- Additional engineering on sealing integrity and swaging action.

- Re-usable and predictable quality.

- Gaugable.

- Excellent leak-free sealing integrity on heavy vibration, vacuum, and impulse.

- Heat-Code Traceability.

- No torque transferring to connective tubing during installation.

Tubing:

For Safe, reliable and leak free DK-LOK fitting system, tubing should be considered as one of fitting components.

- Tubing is assembled by simple wrench make-up on DK-Lok fitting. This results in less assembly and maintenance costs.

- Tubing assembly on DK-Lok fitting is re-usable.

- Tubing is bendable. It allows lower pressure drop with fewer connections. This in turn reduces system costs because of less fabricating manpower.

- Pipe threading or welding is difficult to disassemble and re-assemble

- Piping requires skilled worker for welding & threading

Tubing Selection:

|

Hardness

|

Ovality

|

|

Surface

|

Weld tubing

|

|

Wallthickness

|

Pressure Rating

|

High Pressure Application

Pressure 500 psig (34.5 bar) or higher is considered generally high pressure. In the high pressure system scratches, draw mark, nicks, flat spots, and dirt on tubing may cause leakage.

- For gas application, select the gas applicable tubing wall thickness from Table 2 to 13.

- Follow the suggestion on tubing selection, handling, and installation.

Gas Application

DK-LOK tube fitting is designed for a wide range of leak free application including gas leak proof and vacuum tight service. Gases (helium, hydrogen, nitrogen, air, etc.) can escape even the most minute leak-path due to their very small molecules. Tube therefore must be handled not to have scratches, draw mark, nicks, flat spots, dust, and dirt.

Use NOT thin wall tubing for gas applications. Heavier wall tubing resists the ferrule action whereas thin wall tubing may collapse with little resistance to ferrule action. For Gas service, use the tubing wall listed on un-shadowed section in table 2 to 13.

Vacuum Application

DK-Lok Tube Fittings have been proved to be excellent vacuum tight seal in many applications including analytical industry. DK-Lok Tube Fittings comply with the leakage requirements of TA-LUFT 2002.

Cryogenic Application

DK-Lok Fittings in SS316 Stainless Steel provide highly reliable performance on cryogenic application. Cryogenic temperature is considered to be temperatures below -100℉ (-73℃).

Leave A Comment